Project CV: Novel materials for development of all-optical temperature sensor

Type: European Regional Development Fund (ERDF) project

Duration: 01.10.2020 – 30.09.2023

Budget: total funding of the project is 300 000 EUR, 173 400 EUR of which is ERDF support

Project scientific manager: Dr. habil. Phys., Prof. Uldis Rogulis

Project partner: Light Guide Optics International (LGOI)

The project aims to develop novel transition metal luminescence-based optical materials and a prototype for temperature sensing applications.

So far, the researchers have synthesized new polycrystalline alumina samples activated with manganese ions; the results of experimental measurements of electron paramagnetic resonance, photoluminescence, photoluminescence excitation spectra and quenching kinetics of these samples have been collected and analyzed. Studies of chromium activator in calcium aluminates have been started and continued, and iron activator research in calcium aluminates has begun.

Together with project partner LGOI, a temperature sensor model is being developed in which light signals are transmitted through optical fibers manufactured by LGOI.

The first version of the temperature sensor probe is currently being developed to transfer the excitation signal and collect the luminescence signal. Work is in progress to expand the temperature range of the sensor model. The operation of this temperature sensor will not be affected by surrounding electric and magnetic fields and other environmental factors.

During the project, it is planned to publish four original research publications in journals indexed in international databases (Scopus, Web of Science), submit one patent, and present the project results at international conferences. The applicability of the elaborated optical material will be demonstrated by creating an optical temperature sensor prototype. At the beginning of the project, the technical readiness level was 2 (TRL 2), and at the end of the project, due to prototype development, it is planned to reach the 5th technical readiness level (TRL 5).

More about the project - here.

Project CV: The development of a novel-designed optical fiber-based system for ultra-sensitive point-of-care viral protein detection by SERS

Type: ERDF project

Agreement No: 1.1.1.1/21/A/053

Duration: 2022 - 2024

Total budget: 540 467.91 EUR

ERDF contribution: 442 967,49 EUR

The project is co-financed by the REACT-EU program

Project partners: SIA Ceram Optec

Project leader: Dr.phys. Krišjānis Šmits

To successfully tackle the challenges posed by coronaviruses, the Institute's scientists responded to a React-EU call for additional support in the mitigation of the effects of the pandemic. The project aims to develop a precise and simple-to-use testing system for rapidly determining SARS-CoV-2 spike protein based on surface-enhanced Raman spectroscopy or SERS.

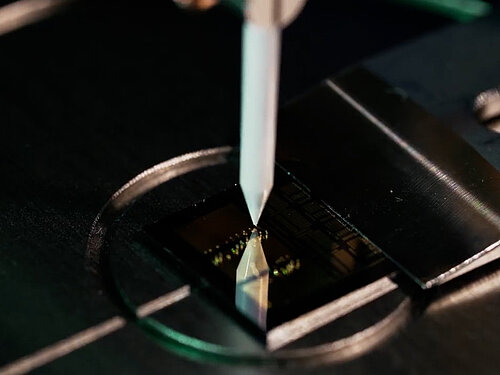

The industrial research project is carried out in collaboration with Ceram Optec, an optical fiber and medical products manufacturing company. The multidisciplinary project includes physics and chemistry, materials science, and nanotechnology research activities. The tasks of the ISSP UL in the project are 1) designing a hardware prototype and software for Raman spectroscopy; 2) developing dedicated fiber optics for SERS; 3) developing an easily exchangeable testing cell for SARS-CoV-2 spike protein detection; 4) and evaluating and optimizing the detection method of SARS-CoV-2 spike protein.

The expected scientific results of the project are three original research publications, accepted for publication in high-level peer-reviewed scientific journals, one Latvian patent, two prototypes of new products (optical fiber bundle and test cell), and presentation of project results at seven international conferences.

More about the project - here.

Project CV: Advanced polymer–ionic liquid composites for sodium-ion polymer batteries

Type: Fundamental and applied research project of the Latvian Council of Science

Agreement No: Nr. lzp-2020/1-0391

Duration: 2021 - 2023

Total budget: 300 000 EUR

ISSP UL budget: 214 530 EUR

Project leader: Dr.chem. Guntars Vaivars

Project partners: University of Latvia, Faculty of Chemistry

The development of lithium batteries changed such areas as electric transport and electrical grid id stabilization devices. However, the new development of new technologies is limited by the availability of lithium and cobalt resources. At the same time, sodium resources are abundant and practically not limited. This fact has renewed the interest in sodium-ion batteries. Sodium ion conducting electrolyte is a basic component of such batteries. Solid electrolytes would be more technological than currently used liquid ones and they are relevant for next-generation - sodium-ion polymer - batteries. This project aims to develop new electrolytes for sodium-ion polymer batteries – membranes based on polymer composites with ionic liquids. The advantage is the possibility to combine both liquid and solid properties in one material. The synthesis of new ionic liquids will be focused on developing innovative materials with a high and selective sodium ion conductivity and decreased hygroscopicity of the final composite. At the end of the project, the new membranes will be used to create a sodium-ion polymer battery prototype.

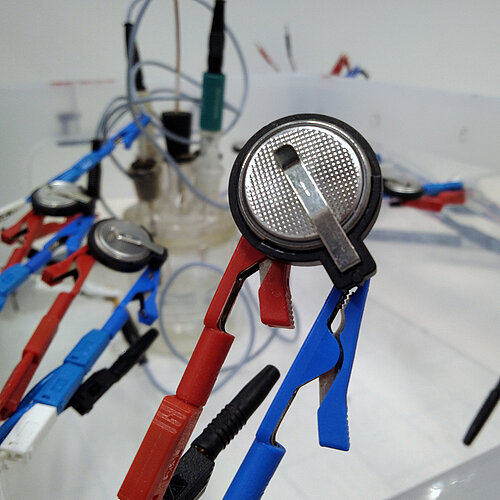

The project is implemented in collaboration with the Faculty of Chemistry of the University of Latvia. The tasks of the ISSP UL in the project are synthesizing polymer membrane composites with ionic liquids, characterizing an electrochemical cell with metallic sodium, and assembling an electrochemical cell prototype.

Project CV: Cycle life prediction of lithium-ion battery electrodes and cells, utilizing current-voltage response measurements

Type: Fundamental and applied research project of the Latvian Council of Science

Agreement No: Nr. lzp-2020/1-0425

Duration: 2021 - 2023

Budget: 300 000 EUR

Project leader: Dr. Phys. Gints Kučinskis

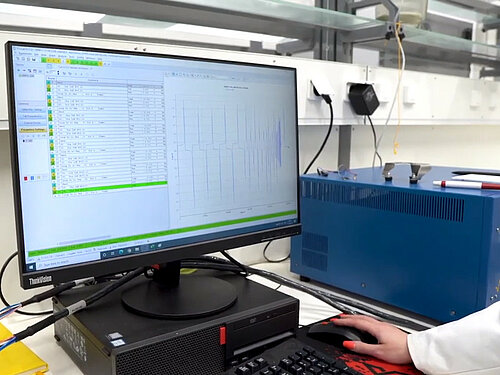

The aim of the project is to develop a novel electrochemical testing routine for a speedy characterization of lithium-ion battery electrodes and cells. In the project, current-voltage response measurements are established and this goes hand in hand with a fundamental understanding of the ageing processes taking place inside the battery cell, which are analyzed by the following methods: XRD or X-ray diffraction (in-situ and ex-situ), scanning electron microscopy (SEM), inductively coupled plasma atomic emission spectroscopy (ICP-AES), energy dispersive spectroscopy (EDS) and X-ray photoelectron spectroscopy (XPS).

Scientists are developing a predictive model that will be verified on lithium iron phosphate (LFP) and nickel cobalt manganese (NCM) based liquid laboratory scale half-cells, full-cells and commercial cells. This model will provide an opportunity to estimate cells’ state of health, rate capability, and life cycle based on a set of short electrochemical measurements, which will be quicker than the conventional charge-discharge cycling techniques.

The new testing routine developed as a result of the project will allow for speedier testing of electrode materials and recipes for electrode preparation and an improved measurement speed when assessing the life cycle and state of health of commercial cells.

Project description is here.

Spectromarine – project CV

Full name of the project: Smart buoy for the monitoring of aquatic organisms and assessment of water quality

Type: Investment and Development Agency of Latvia (LIAA) mission “Sea 2030”

Duration: June 1, 2022 – June 30, 2023

Total budget: 222 222.22 EUR, from which 200 000.00 is European Regional Development Fund budget (90%)

Project manager: Dr. Phys. Aleksejs Zolotarjovs

The Spectromarine project aims to develop an autonomous and energy-independent buoy for monitoring water quality and indicators of aquatic microorganisms.

Sea pollution in the Baltic region creates hazards to human health and marine organisms and can cause devastating economic losses. This project offers technology for water quality monitoring – a brief online in-depth analysis of saltwater. The technology is a portable, autonomous, fully automated spectroscopy laboratory buoy with networking capabilities. It consists of three parts - a novel spectrometer device attached to a buoy, data acquisition/analysis software running on a microcontroller, and a cloud-based database with reference sample data. The main aim of the device in the scope of this project is a data-driven assessment of water quality directly affecting sea farm products. However, the device can be used in other fields where continuous water quality measurements are needed (ecology-focused government organizations, harbors, oil platforms, etc.). The novelty and market advantage of the technology lies in its two main properties - a significantly reduced cost of the device when compared to the alternatives and the use of a novel spectrometer offering a much broader range of data, thus expanding the list of measurable pollutants, be it through direct or indirect measurement.

The ISSP UL performs all tasks in the project: buoy prototype development (including data processing algorithms, servers, and communication protocols) and communication with industry and market analysis for successful commercialization of the Sepctromarine.

The aim of the project is to create a prototype of laser-induced spectroscopy-based technology and measurement device for determination of soil carbon concentration and to apply this technology in real conditions in agriculture.

The carbon in the soil is essential for the yield and quality of plants, it releases nutrients necessary for growth, improves the biological and physical health of plants, helps against pests, acts as a buffer against harmful substances, and helps to maintain the necessary level of mineral fertilizers in the soil, reducing the consumption of fertilizers in agriculture. To maintain the carbon concentration at an optimal level, it is necessary not only to take proactive actions on the part of the farmer to capture carbon in the soil, but it is also necessary to ensure the possibility to determine and monitor this concentration. Currently, this can be done by analyzing soil samples in laboratories, but this is time-consuming.

As a result of the implementation of the project, innovative technology was created - the determination of soil carbon concentration by the method of laser-induced spectroscopy and the mapping of the obtained results, where the obtained results allow farms to carry out activities that increase the concentration of soil carbon in the existing agriculture. By using a portable device based on the mentioned technology, the farmer can quickly determine the concentration of soil carbon in the entire agricultural area and later pay attention only to problematic areas, thus saving labor and energy resources and developing smart agriculture.

The technology developed during the project was used to obtain carbon concentration measurements from real fields in cooperation with the company SIA "Latvijas grauds".

Project description here.

SunToChem Project CV

Full name of the project: Engineering of perovskite photocatalysts for sunlight-driven hydrogen evolution from water splitting

Type: EraNet

Duration: 2019 – 2022

Budget: 200 000 EUR

Project partners: Advanced Materials Department, Jožef Stefan Institute, Slovenia (project coordinator), and Department of Chemical Engineering, National Taiwan University, Taiwan

Project coordinator in Latvia: Dr.habil.phys. Eugene Kotomin

Climate change and energy shortage are the major challenges for which science and technology are expected to provide effective solutions. Despite the enormous free energy supply from the sun, most of the world’s energy consumption (87 %) comes from fossil fuels, which are firstly limited and secondly, emit excessive CO2 causing global warming. Intensive scientific efforts are going on in different fields to increase the solar share from currently less than 1% of total energy consumption to higher values. One of the viable approaches is to use solar light together with photocatalysts for the driving of chemical reactions. Sunlight-driven water splitting is regarded as one of the most attainable and sustainable strategies for producing hydrogen, a storable, pollution-free energy source.

In this project, the latest knowledge in density functional theory (DFT) calculations (Riga team), particle engineering (Slovenian team) and reactor design (Taiwan team) are combined to enhance the understanding of chemical and physical properties in photocatalytic process and to design the effective photocatalysts based on perovskites crystallites.

More about the project – here.

Project CV: Eco-OLED

Full name of the project: Enabling a Commercially Viable Long Lifespan and High-Efficiency Omni-Friendly OLED Lighting Source with G2 and G3 Emitters

Type: EraNet

Duration: September 2020 – August 2023

Budget: 600 000 EUR

Project coordinator: Prof. Jwo-Huei Jou (National Tsing-Hua University, Hsinchu, Taiwan)

Project parnters: Riga Technical University (RTU), Kaunas University of Technology (KTU)

Project leader from ISSP UL: Dr. Aivars Vembris

The spectrum of sunlight can be imitated by organic light-emitting diodes (OLEDs). Replacing the current artificial lighting elements with OLEDs could be a way of preventing melancholy or even suicide, as the northern countries lack sunlight during the long winter. However, the difficulty of controlling the desired color and brightness at the same time has hindered the further commercialization of this invention for many years. We have finally been able to develop some new approaches to create natural-style emissions that are not only color temperature and brightness adjustable, but also relatively high in terms of brightness and light quality.

The aim of the project is to achieve an all-friendly OLED with color temperature adjustable from 1400 K to 5500 K, SRI> 95, lifetime> 60,000 hours, power efficiency of 140 lm / W and to produce a commercially viable prototype OLED panel with a radiant area of 5 x 15 cm2 or 10 x 10 cm2 to meet market demands and increase the competitiveness of our lighting industry.

The international consortium includes four partners: Partner 1 (Taiwan) is responsible for the development of a high-efficiency light-emitting diode; Partner 2 from Latvia (ISSP UL) investigates the light emission and electrical conductivity properties of the newly synthesized materials. The 3rd and 4th partners, from Latvia (RTU) and Lithuania (KTU), respectively, deal with the synthesis of second and third generation organic light-emitting molecules. The project envisages technological development up to TRL 4 level.

Project description here.

Project CV: ZMOMUVS

Full name: ZnMgO materials with tunable band gap for solar-blind UV sensors

Type: EraNet project

Duration: September 2019 – August 2022

Budget: 210 000 EUR

Project coordinator: Prof. Mitch Chou, National Sun Yay-Sen University, Kaohsiung, Taiwan

Project leader in Latvia (ISSP UL): Dr. Laima Trinkler

Deep UV photon sensors based on wide bandgap semiconductors can be used as biological and chemical sensors for ozone detection, water purification detectors, and determining pollution levels in any biological agent. The concept of this project is to use the ZnO-MgO pseudobinary system, which has a tunable bandgap from 3.3 eV to 7.8eV, thus significantly enhancing the ability of the sensor to detect signals at different energies simultaneously. The limitation of ZnO and MgO mutual solubilities can be broken by stablizing the high MgO-content wurtzite Zn1-xMgxO and high ZnO-content rocksalt Zn1-xMgxO epilayers by using low lattice mismatch substrates such as ScAlMgO4, MgO and Cu2O.

The project involves five partners who have formed an international project consortium: two partners from Taiwan are responsible for the growth of single crystal substrate and epitaxial growth of ultra-wide bandgap Zn1-xMgxO epilayers/heterostructures as well as fabrication of solar-blind UV photon sensor devices. In turn, three partners from Latvia and Lithuania are studying the optical and electrical properties of the new materials. The results of these studies will help Taiwanese scientists to choose the optimal parameters for growing ZnO-MgO films. In addition, the Latvian side performs computer modeling of the material structure, providing theoretical support for the project.

Participation in this project will help to increase the technology readiness level of all partners: up to TRL 4 in Taiwan and TRL 3 in Latvia and Lithuania. The project itself will bring benefits to each partner and provide new contributions to European society.

Project description here.

The project has two phases. The first phase was aimed at developing a commercialization strategy and technical and economic feasibility study for the commercialization of an optical gas sensor and it has already been completed. The aim of the second stage is to commercialize the optical gas sensor that can detect various volatile organic compounds and gas concentrations in the air.

The main advantages of this technology are high sensitivity, fast response, robustness, and simple fabrication. The range of potential users of optical gas sensors is wide, from industry to environmental monitoring at home. The sensor is made from inert materials that allow it to be used in aggressive environments such as farms with a constant ammonia concentration.

Full project description here.

‘Strengthening the doctoral capacity of the University of Latvia within the framework of the new doctoral model’ Project CV

Type: ESF project

Duration: 01.07.2021.-31.10.2023.

Total funding: 4 208 666.00 EUR (European social fund co-financing 3 577 366.10 EUR, state budget co-financing 631 299.90 EUR)

Main partner: University of Latvia

Project Manager: Dr. Phys. Anatolijs Šarakovskis

The project aims to establish cooperation between the University of Latvia and the Institute of Solid State Physics, University of Latvia (ISSP UL), towards including PhD students and PhD candidates in study and research work. The project's main results are to support the attraction of doctoral students/degree candidates and foreign academic staff and the implementation of further cooperation. The project envisages the involvement of doctoral students in study or research work, attraction and employment of foreign academic staff, and project management.

One of the activities of this project is to support doctoral students and applicants for a scientific degree to promote their academic activities at the University of Latvia, which means that after participating in the project, young researchers are encouraged to continue their academic careers. For their part, the project partners provide an opportunity for future researchers to work on their dissertation and be employed in research or development projects related to the dissertation’s topic.

During the implementation of the project at least five PhD students will have defended their doctoral thesis and started their exciting careers as scientists at the ISSP UL.

Read about the project here.

Development of holographic recording materials based on azo-benzene and epoxy compounds - Project CV

Type: European Regional Development Fund project (administered by Investment and Development Agency of Latvia (LIAA))

Duration: 1st phase from 01.04.2020 till 30.09.2020; 2nd phase from 01.12.2020 till 30.09.2022

Total budget: 305 000 EUR

ISSP UL funding: 30 000 EUR

Project leader: Dr. phys. Jānis Teteris

The project aims to study photoinduced mass transfer processes in thin films of amorphous chalcogenide and azo-benzene organic compounds and develop a new type of photoresists for holographic recording that do not require chemical treatment after exposure to light. The surface relief gratings on the photoresist are formed directly during the exposure of the holographic recording due to the interaction of light and material. Thus, it is a single-step lithographic process that does not require the use of harmful chemicals in the production of holographic elements.

Three prototypes of the holographic recording equipment or training kits are being developed during the project based on the previously developed holographic recording materials. Prototype No. 1 demonstrates recorded elementary holograms - diffraction gratings of different periods, but prototype No. 2 demonstrates the recorded elementary holograms – diffraction gratings and includes kinetics and parameter measurements. Prototype No.3 is designed to practically show the process of holographic recording of a real dimensional image. For this purpose, a recording scheme to be used in the student learning process is being developed: the dimensions of the scheme have been optimized, and the compatibility of components has been tested, including the testing of different types of microscope lenses required for beam splitting in case of a dimensional object recording. It is also planned to develop methodological guidelines for the use of the study kit in the teaching process.

The project plans to improve these prototypes to be used in the teaching process in secondary schools in Latvia. The further commercialization process would consider options for mass production and distribution of the study kits.

The full project description is here.

Fabrication of various organ-on-chip devices has been taking place at the ISSP UL for several years now and owing to the specific knowledge and experience base, the “Mass-manufacturable gut on a chip” project is now being implemented by the Micro and Nano Devices Laboratory.

The project aims to develop a gut microphysiological device that is compatible with mass-manufacturing processes. Gut-on-chip is a microfluidic device or synthetic mini-organ that allows the replication of certain human gut functions outside the human body by recreating the interface between epithelial and endothelial human cells. Technology can be utilized to discover new drugs and treatments for various diseases. The use of such a device allows for bolder and more daring experiments that would not otherwise be possible. In the future, organs on chips will have the potential of replacing animal testing and reducing risks in clinical trials.

The project aims at developing a commercialization strategy and experimentally demonstrating the possibility of making gut on chips using manufacturing-scalable materials. The project consists of two phases: the first, already completed preparatory phase, during which a feasibility study and a commercialization strategy of the technology transfer project were developed, whilst during the second phase device prototypes are developed with the aim to select materials and optimize device design for production. The manufactured prototype will be tested in experimentally representative conditions.

The full project description is here.

Project CV: Semi-transparent thin film solar cells

Full name: Development of Semi‐Transparent Bifacial Thin Film Solar Cells for Innovative Applications

Acronym: BTSC

Type: EEA and Norwegian grant project

Duration: January 2021 – December 2023

Budget: 999 372 EUR

ISSP UL financing: 200 000 EUR

Partners: Kaunas University of Technology, Lithuania (KTU), Tallinn University of Technology, Estonia (TalTech), and Institute for Energy Technology, Norway (IFE)

Coordinator: Dr. Vytautas Getautis (KTU)

Project manager at ISSP UL: Dr. Aivars Vembris

The project aims at developing cost-effective semi-transparent bifacial thin-film solar cells that operate efficiently in both intense and low sunlight. This means that light can be collected not only in sunny weather but also in the dark autumn and winter months. Solar cells like that would look like semi-transparent films, would have limitless potential - they could be used on the shady sides of houses, electric car windows and architectural elements. The potential of the solar market for household applications in the Nordic and Baltic countries would be limitless.

The project builds on the pre‐existing complementary scientific expertise in the related fields of synthesis of novel organic and inorganic hole conductor materials carried out at the KTU and their characterization, which in turn is implemented by the ISSP UL. Thin film deposition and solar cell fabrication are carried out at TalTech, while the IFE implements material modelling and defect chemistry by first-principles calculations as well as solar cell device modelling.

The synergy of joint research collaboration gives novel input to developing such solar cells for innovative applications. The project stimulates collaborative research on EU and regional levels and offers splendid possibilities for PhD and postdoctoral students’ research.

The full project description is here.

CV of AliCE -WHy project

Type: EEA and Norwegian grant project

Duration: 1.05.2021 - 30.04.2024

Budget: 800 000 EUR

Co-financing: 120 000 EUR

ISSP UL financing: 245 000 EUR

Partners: Lithuanian Energy Institute, University of Iceland, IceTec (formerly known as Iceland Innovation Center Iceland)

Project manager: Dr.phys. Jānis Kleperis

Proper waste management and energy production play a key role in ensuring sustainability. Aluminum (Al) is a strategic material with a wide range of applications. Although Al is a recyclable material, two problems arise: 1) its recycling is an energy-intensive process because Al has to be remelted at 2072℃; 2) the unprocessed and semi-recycled material generates a huge amount of unprocessed Al waste. Despite the fact that Al waste is recycled, there are still many polluting landfills in Europe. The main idea of the project is to solve the recycling of Al for clean energy production and to create a prototype of such technology.

The essence of the project is also included in its name - Aluminum in a circular economy - from waste through hydrogen energy to alumina or AliCE-WHy. As the name suggests, scientists aim at developing new technological solutions for the recycling of aluminum waste, increasing its efficiency and ultimately producing hydrogen that can be used in energy production. Aluminum residues, oxides and hydroxides are also generated in this process, which can be further converted into useful γ-alumina, ensuring higher recycling and energy of the materials used.

Four partners are involved in the implementation of the project, each with its particular task: the Lithuanian Energy Institute investigates the treatment of Al waste to produce hydrogen; IceTec addresses the possibility of recycling of produced reaction by-product to Al and/or other useful materials; the University of Iceland evaluates the techno-economic and environment impact of the proposed process on Iceland and the Baltic States; the ISSP UL analyzes the purity of the generated hydrogen gas and coordinates the development of a prototype design.

The full project description is here.

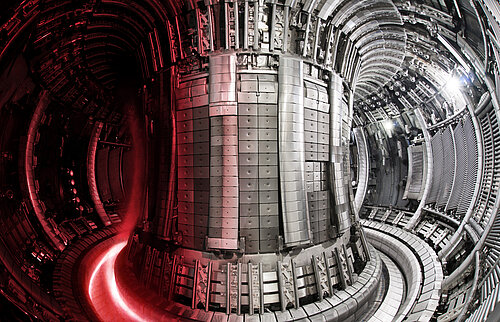

EUROfusion is an example of successful cooperation between the European Commission (EC) and the international fusion community, bringing together all European Union (EU) countries, the United Kingdom, Switzerland, and Ukraine.

EUROfusion is one of the largest research programs in Europe and its aim is to develop fusion as a viable energy source by 2050. Fusion, the process that powers stars like our Sun, promises an almost limitless source of CO2-free electricity, using small amounts of deuterium and tritium fuel that can be sourced worldwide from inexpensive materials. The fusion process brings together atoms of light elements like hydrogen at high temperatures and pressure to form helium and release tremendous amounts of energy.

The aim of the EUROfusion program is to prepare for ITER (International Thermonuclear Experimental Reactor) experiments and to develop concepts for the future European demonstration fusion plant DEMO. The members of the consortium receive funding for fusion projects in accordance with the European Research Roadmap for Fusion Energy. In February 2022, it was announced that EUROfusion researchers from across Europe had taken a major step towards launching the ITER - the world's leading fusion facility, the Joint European Torus (JET), reached a record 59 megajoules of continuous fusion energy.

Under the management of Dr. habil. phys. Andris Šternbergs, the ISSP UL’s scientists have joined forces with the researchers from the Institute of Chemical Physics, University of Latvia and the Institute of Physics, University of Latvia and have successfully participated in solving the problems of fusion both in the previous EU framework programs and in the new EUROfusion project within the Horizon Europe program.

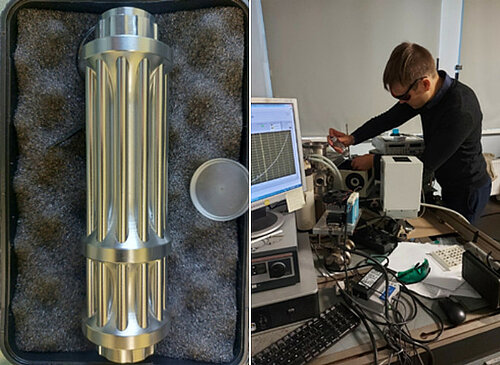

Scientists at the ISSP UL study the stability of materials under the influence of radiation and a strong magnetic field. The structure of materials is studied with the help of computer modeling, and their compliance with the actual material properties is tested experimentally. This provides an understanding of the mechanisms of defect occurrence, as well as ways to eliminate these defects so that the structural elements of the thermonuclear reactor last longer during its operation. The materials used in the construction of fusion reactors are also studied by laser spectroscopy (LIBS) and X-ray absorption (EXAFS) methods.

The research of Latvian scientists is aimed at studying and improving the materials and processes that take place in fusion reactors, thus facilitating faster entry of fusion energy into the world.

More about the EUROfusion at ISSP UL find here

CV of the CAMART2 project

Type: EU “Horizon 2020” Teaming project

Duration: 01.02.2017. – 31.01.2025

Budget: ES 14 999 955 EUR

Attracted additional funding: ERDF 12 072 166 EUR, State 1 248 030 EUR; ISSP UL 2 000 000 EUR

Partners: Royal Institute of Technology (KTH, Sweden), Consortium of Research Institutes of Sweden (RISE)

Manager: Dr.phys. Mārtiņš Rutkis

To reduce inequality in the development of research and innovation between the new and old EU Member States, a call for teaming projects under the EU's Horizon 2020 research and innovation framework program was launched. The condition for participation was that the best of the least developed EU countries and the best of the most developed countries join for cooperation. Withstanding huge competition (5th place from 169 applications), the Institute of Solid State Physics, University of Latvia (ISSP UL) was one of the winners with the project Center of Advanced MAterial Research and Technology Transfer – CAMART2.

The project advisers are ISSP UL’s partner institutions, world-class experts in innovation and technology transfer – KTH and RISE. Together, we are transforming our Institute into a significant center of excellence of materials science not only in Latvia but also in the Baltic Sea region; into a center able to operate effectively in the international research and innovation environment, as well as to cooperate successfully with representatives of various industries.

The young generation of today is the one who will continue to carry on the good reputation of Latvia and ISSP UL in the world. In cooperation with the Department of Physics of the University of Latvia, a new master’s degree study module has been established, which now includes courses on modern materials and technologies. During the project implementation, the Institute has experienced huge transformation - an innovation and technology transfer ecosystem has been created, the new equipment has been purchased, and laboratories have been renovated, establishing a modern European-level research environment for efficient work.

The impact of such large-scale projects is measurable in the long term. Modern infrastructure, well-organized environment, improved and new skills, reliability among partners, ability to help the industry, creation of new materials, solutions to scientific or practical problems, important publications, and smart scientists - this is the place for the outstanding new generation of young scientists because passion drives progress!

Project homepage www.camart2.eu