- Project title: Aluminium recycling for hydrogen production - from waste through hydrogen energy to alumina - AliCE-WHy (Aluminium in a circular economy - from waste to hydrogen energy to alumina "- AliCE-WHy)

- Project number: EEA-RESEARCH-92

- Implementation period: 1.05.21 - 30.04.2024

- Allocated Funding: EUR 800,000

- Co-financing: EUR 120,000

- CFI Financing: EUR 245,000

- Aim of the project: The aim of AliCE -WHy is to create a technological solution for the recycling of aluminium waste, increasing the efficiency of recycling, the end result of hydrogen for energy use and the production of further low-emission alumina products.

- Expected results:

- Waste aluminium treatment methodology for its use in hydrogen production

- Prototype for electricity generation from Aluminium scrap.

- Methodologies for further processing of reaction products generated in the prototype The evaluation of the obtained technology has been approbated with the socio-economic evaluation in the context of Icelandic and Baltic aluminium waste recycling.

- Developed methodology for aluminium waste treatment

- A prototype for electricity generation from aluminium scrap has been developed

- Developed methodology for obtaining alumina in processing

- A socio-economic assessment of the developed technology has been prepared

- Partners:

- Contact person: Ainārs Knoks ainars.knoks@cfi.lu.lv

- Project manager: Dr. Phys. Jānis Kleperis, Institute of Solid State Physics, University of Latvia

- Active links: https://eegrants.lv/ and https://eeagrants.org/

- Title of the program: “The project is co-financed by the European Economic Area financial instruments for 2014-2021”

Project goal:

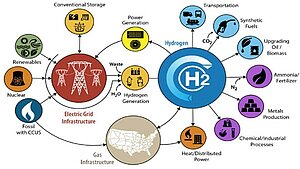

The main idea of AliCE-Why is to tackle aluminium (Al) recycling for clean energy production. Al demand is evermore increasing as well as energy production, but recycling possibilities are relatively scarce in small country or remote location context. In addition, transportation of current waste Al requires additional costs and does not generate jobs and revenue on unused resources that are exported. Thus, a local cyclic process for recycling should be developed. Main goal of this project is to develop technology and prototype for power generation form waste Al through production of hydrogen and further recycle by-product Al hydroxide.

Fig. 1. Adopted from Haller et al. https://doi.org/10.1016/j.ecmx.2019.100017.

Project summary:

Currently, waste management and energy production are recognized as essential field for world sustainability assurance. Aluminium (Al) is a very important strategic material in Europe with wide variety of application areas. Unfortunately, this invokes huge amount of waste Al generation. Despite that part of waste Al is recycled, there are plenty of landfilled Al, which pollutes environment. Therefore, during this project, we will initiate scientific and engineering activities revealing innovative ways for waste Al application on electricity generation using hydrogen produced after waste Al-water reaction.

Obtained reaction by-product can be further recycled back to Al via carbon free electrolysis. Also, by-product can be used as a precursor for other valuable materials production. All the mentioned processes will be realized as a prototype.

The project will involve: investigation of the waste Al treatment for hydrogen production (Lithuanian Energy Institute); analysis of generated hydrogen gas purity (Institute of Solid State Physics University of Latvia (ISSP)); recycling of produced reaction by-product to Al and/or other useful materials (Innovation Center Iceland); evaluation of techno-economic and environmental impact of proposed process on Iceland and Baltics (University of Iceland), prototype design (coordinated by Latvian team). The project Consortium consists of four partners with main tasks mentioned above, which will ensure close cooperation and successful project realization.

Fig. 2. As Project has brought inspiration from works of Haller et al. the project core idea and concept is explained by the schematic.

Keywords: waste-to-resource, hydrogen, circle economy, aluminium recycling.

PROJECT PROGRESS INFORMATION

Period 01.05.2022. - 31.07.2022. | 14.09.2022.

We have reached the following milestones for the first year:

- 2.1. Electrolyte selection – we have selected electrolyte for further experiments, but in the final analysis the electrolyte will be revised in the socioeconomic analysis

The choice of electrolyte for the water-aluminum reaction affects the final process cost, environmental impact, reaction activity and benefit, among other aspects. Therefore, it is important to choose an optimal electrolyte. For now, NaOH has been chosen, but it will be possible to reassess the scalability and impact of this hydroxide after a socio-economic assessment by the Icelandic partner, the University of Iceland.

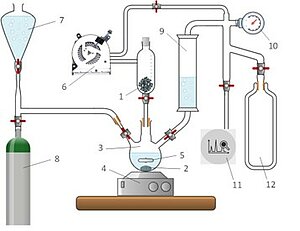

- 2.2. Small scale H2 production set-up

The Lithuanian partner, the Lithuanian Energy Institute, has created a small-scale experimental facility for aluminum-water reaction research. Both the technical aspects of the creation of this device and the effect of the electrolyte on the release of H2 at different temperatures were studied. It has been observed that increasing the temperature also increases the rate of H2 release, but the amount of precipitated alumina, hydroxide and oxyhydroxide materials mixes with other by-products, thus reducing the amount of useful alumina obtained at the end.

- 3.1. Inline GC and MS reactor set-up (Fig.1). In order to analyze the purity and composition of the obtained gases, depending on the various waste products of aluminum in the reaction with an alkaline aqueous solution, a reactor was created with the possibility of gas chromatography (GC) and mass spectroscopy (MS) measurements. Evidence has been obtained that at least 98% of the gas released in the reaction is hydrogen.

- 4.1. By-product investigation

Participation in FM&NT – NIBS conference July 2022

Presentation by Dr Camila Pía Canales, “The decade of hydrogen: where are we heading to?”

Organisation: Faculty of Industrial Engineering, Mechanical Engineering, and Computer Science, University of Iceland. Overall idea can be represented by the figure below

As a result of the reaction with water, solid aluminum forms aluminum hydroxide, oxide, oxide-hydroxide and other compounds. In order to evaluate the quality of the deposits and how much useful material can be obtained from these deposits, deposits were dried, analyzed and calcined, after which the mass change, surface area and amount of aluminum oxide of the obtained material are evaluated. At this stage of the project, a preliminary analysis has been carried out and it can be seen that it is necessary to assess the impact of the formed carbonate in more detail; as well as the real source/reaction.

All partners have actively participated in the project, even though formally, some packages have not started yet. That has proven to be very valuable Extensive knowledge of treatment by LEI has shown great promise in H2 production efficiency (up to 3 times compared to non-treated) Chemical and industry knowledge of UI and IceTec has been irreplaceable in identifying important parameters, results and possible use of investigated reactions and materials such as industrial use, source of raw materials, possible contamination by environment and others With valuable input from partners ISSP UL has created testing set-up and first drafts of the reactor prototype

Presentation by Dr. Sarunas Varnagiris “Plasma treatment application for green hydrogen production via hydrolysis of waste aluminum in alkaline water”

Lithuanian Energy Institute

Conclusions:

Plasma increased hydrophilicity of Al powder surface and greatly improved H2 production yield. The effect of plasma on Al chips did not appear to be as good as on powder, and more alkali was required to obtain a similar yield of H2. The reaction byproduct could be a promising precursor for the production of ceramics or catalyst substrates.

In addition poster presentation were given at the same conference:

Raitis Kaspars Sika et al. “Reactor design investigation for Hydrogen production from Aluminium -Water reaction”

Presented thesis

- The simulated flow of liquid is practically identical to real life; the simulation can predict particle settling location with good accuracy which is important for the further development.

- Additional simulations, with different sized meshes should be carried out for further data gathering and reactor design improvements.

- The gained results can be used in future for more efficient reactor designs and current reactor development

Ainars Knoks et al. “Electrochemical Corrosion Behavior of Aluminum Foil – investigation of kitchen wastes”

Presented thesis

From the semicircular forms in high-frequency region, charge transfer can be estimated.

The increase of temperature should influence the charge transfer thus impedance should decrease, on the other hand during the process oxides and hydroxides are created, which should lower the activity; electrolyte composition can mitigate the passivation of the active sites i.e. promotion of hydrogen production. Currently gained results show charge transfer impedance is growing with the increase of temperature which could indicate growth of oxide/hydroxide. At the same time impedance of the electrolyte through the deposition layer is decreasing and double layer capacitance is also decreasing. This indicates corrosion is happening, alternatively, it could be cracks in the electrolyte/particle boundary layer. And on the last note, the electrolyte ion diffusion impedance seems to be increasing.

Ansis Mezulis et al. “On the efficiency of hydrogen production from plasma-treated aluminum waste with NaOH and KOH promoters”

Presented thesis

Concluding that applied pre-treatment of aluminum by hydrogen plasma gives obvious results: in the first stage, hydrogen production efficiency increases up to 10 times, whereas the activation energy reduces by 18%. The most likely explanation for the benefit is that surface irregularities, created by the plasma treatment, could initiate the formation of the cracks in a natural aluminum oxide layer and help the water to penetrate into depths of material and react with pure aluminum.

Period 01.08.2022. - 01.02.2023. | 23.02.2023.

ISSP has investigated reactor design and experimental setup for hydrogen production through combination of simulation model as well as real life prototype of that model. It is clear that at larger scale mixing of electrolyte and aluminium material will pose a problem. Thus, flow simulations and reactor was also modeled and is planned to be further tested.

IceTec has done reaction by-product investigation and treatment of aluminium hydroxide to identify how initial parameters influence properties and amounts of the by-product.

University of Iceland has conducted the investigation and evaluation of processes used in aluminium recycling to identify proper evaluation methodology and comparison parameters. Main aluminium sources that could be used in the process have been identified.

Dissemination was carried out in various events, such as

- The successful connection to fuel cells and production of electricity was demonstrated in social media posts for Summer solstice

- At the inventors fair MINOX and in the international scientists night. At MINOX AliCE-WHy prototype was voted to bronze medal in innovation.

- Presentation at “OSCE central Asia delegation visit to Reykjavik”, 11-13 October 2022

- Project was presented at exhibition for general public in Klaipeda “Without waste” and win a best innovation award

- Social media posts such as Twitter post , twitter, or LinkedIn as well as updates on project ResearchGate page.

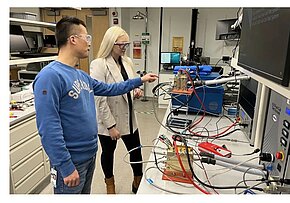

In addition UI partner visited UC Berkeley for project presentations and excursion where here Camila is shown local laboratory equipment.

In February it is planned to have joint workshop with REVEAL project from Switzerland (https://www.reveal-storage.eu/).

Period 01.02.2023. - 01.04.2023. | 03.04.2023.

As planned in February the project had a joint workshop with REVEAL project from Switzerland (https://www.reveal-storage.eu/ ), where current and previous results were discussed. Groups agreed to look for further opportunities to collaborate in the future.

As a part of the project, Kārlis Grava, a student of the Riga State German Gymnasium, received a second degree diploma at the 47th Latvian students' conference of scientific research works in the group of natural sciences. Kārlis conducted a study on the effect of seawater on the AliCE-WHy process.

Period 02.04.2023. - 01.08.2023 | 02.04.2023.

The project consortia submitted 2 publications, first pre-print available here (https://www.preprints.org/manuscript/202304.0428/v1 ), and it has been published here (https://www.mdpi.com/1996-1073/16/14/5554).

The banner is below.

Ainars Knoks gave an interview on a radio show Zinatnes vārdā for Radio Naba (https://naba.lsm.lv/lv/raksts/zinatnes-varda/iemet-aluminiju-udeni-un-savac-udenradi.a174291/ )

Annual project meeting was held in May of 2023 in Kaunas and consortia participated in the CYSENI confrerence.

Consortia group photo below.

Ainars Knoks and Peteris Lesnicenoks gave a presentation on the EEA program and project results to the donor country representatives.

Projet results were presented at V World Latvian scientist congress “Zinātne Latvijai”

Presented by Ainārs Knoks, recording in latvian can be viewed here : https://www.youtube.com/live/xFcv8aDI7i8?feature=share&t=3151

Visit to Laurance Berkeley Laboratories – Talk to Prof. Weber research group (December 2022)

Visit to UC Berkeley, CA – Visit to Prof. Enrique Iglesia and talk about CO2 management in catalytical processes. (December 2022)

Talk with MSc. Erlendur Kristjánsson, Silicon Valley, about costs and profits from AliCe-Why vs. other processes (April 2023)

LEI Hydrogen Technology Team implemented the hydrogen energy technology training program for industry in Lithuania. During the training, the activities of the AliceWhy project were also presented.

The Spanish Ambassador and the Economic and Trade Attaché of Spain visited the Lithuanian Energy Institute. During the visit, the guests were shown a demonstration of hydrogen generation technology showcasing the use of aluminum and water reactions.

Students from Italy, Croatia, Romania, and Lithuania visited LEI and were introduced to various projects related to hydrogen energy, including the AliceWhy project.

Representatives of the Lithuanian District Heating Association visited LEI. Members of the association were introduced with the work carried out by LEI scientists and discussed the possibilities of closer cooperation in the field of innovation.

The leading researcher from the LEI team at AliceWhy, participated in the event "Hydrogen: The missing piece of the puzzle for climate neutrality" in Brussels. During the event, he delivered a presentation highlighting the research and development activities on hydrogen in Lithuania, including the project idea and the results achieved in the AliceWhy project.

During the visit to the School of Engineering at Aberdeen University in March, Dr. Šarūnas Varnagiris presented Lithuania's position on the Hydrogen Economy, which included activities related to the AliceWhy project

Period 01.08.23 - 30.04.24

During this period, the course of the project and its final seminar, the meeting of all partners in Iceland has developed rapidly.

During this period, the consortium participated in the EIT InnoEnergy Hello CleanTech 2.0 Startup Challenge

Published article: “Enhanced hydrogen generation through low-temperature plasma treatment of waste aluminium for hydrolysis reaction”

Two more articles were submitted: “Recycled aluminum, energy consumption, hydrogen production, aluminum oxides, circular economy, electrolysis”

“Investigation of Aluminium white dross for hydrogen generation via hydrolysis”

These two are awaiting reviewer comments.

A patent was submitted and approved in Lithuania "A method for drying and storing hydrogen produced by alkaline water electrolysis" Tag : PAT2024/1, Date : 30.04.2024 Application number : LT2024 518

Ainārs participated in the SWH radio show "Mind will save the world", where topics and open aspects related to hydrogen and the project were discussed. ▶ Radio show recording

The results of the project were also presented to representatives of various industries and scientific institutions, such as Korean POSCO, KITECH, RIX and others.

The project was told in Lithuania as part of the event "Hydrogen Lithuania: Energy and Mobility" (part of Central and Eastern Europe H2 Bus Roadshow), Vilnius, Lithuania.

The results of the project were presented at the WORLD TURNS DEEP TECH event.

The last meeting of the consortium was held, results and further actions were discussed. As usual, a very productive and promising meeting.

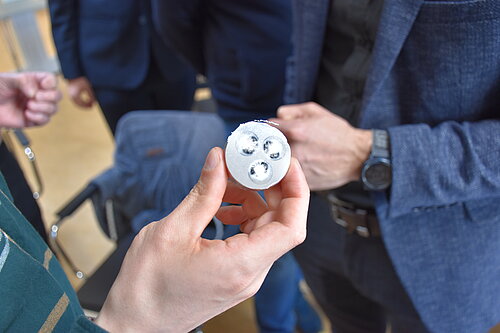

Using aluminum waste and hydrolyzing it with the electrolyte of choice produced aluminum hydroxide, which was further converted to gamma alumina and finally to metallic aluminum, which we see in this image. Which shows that using the AliCE-WHy process, a true circular economy application is possible with a complete waste2product process and the conversion of unused aluminum waste into metallic aluminum.

Also, at the end of the project, the developed prototype was completed and launched, the summary of which can be seen in the video below. Moving forward, the consortium has drawn up immediate and further action plans and directions, new opportunities will be sought to continue research and use the acquired knowledge in the development of further technologies and processes.