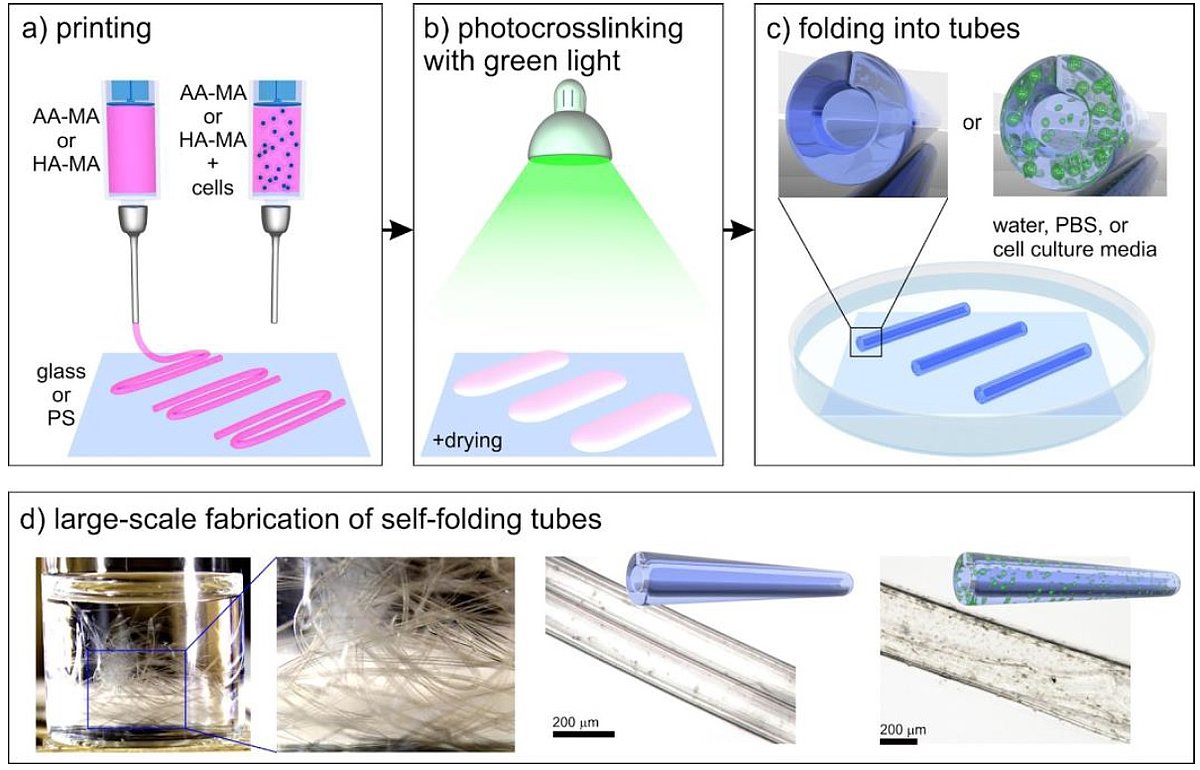

We utilize biologically inspired strategies to develop new functional and active 3D (bio-)materials based on actuating polymers for soft robotics, smart textiles, soft electronics, energy storage materials, and tissue engineering as well as for a variety of other scientific and industrial applications. Particular focus is processing of stimuli-responsive, shape memory polymers and hydrogels. To process various polymers we use fused filament printing, extrusion printing of hydrogels, ink-jet printing, electrospinning, meltelectrowring as well as stereolithography. Our particular focus is 4D biofabrication, which is fabrication of cellular structures by shape-transformation of 3D objects. We pioneered fabrication of 4D biofabrication using most important biodegradable polymers, which are widely used in tissue engineering, such as gelatin, alginate and hyaluronic acid.

Baltijas-Vācijas Augstskolu biroja projektu finansiāli atbalsta Vācijas Akadēmiskās apmaiņas dienests (DAAD) no Vācijas Ārlietu ministrijas piešķirtajiem līdzekļiem.