The core of Nanotechnology centre is 650 m2 large cleanroom with cleanliness ranging from ISO 4 to ISO 8 with state-of-the-art equipment and expertise for cutting edge nano and micro fabrication both in fundamental research and device development.

|

|

| Cleanroom ensures continuous improvements and quality control based on ISO 9001:2015 certificate | Nanotechnology centre is a part of EUROnanoLAB |

EXPERTISE

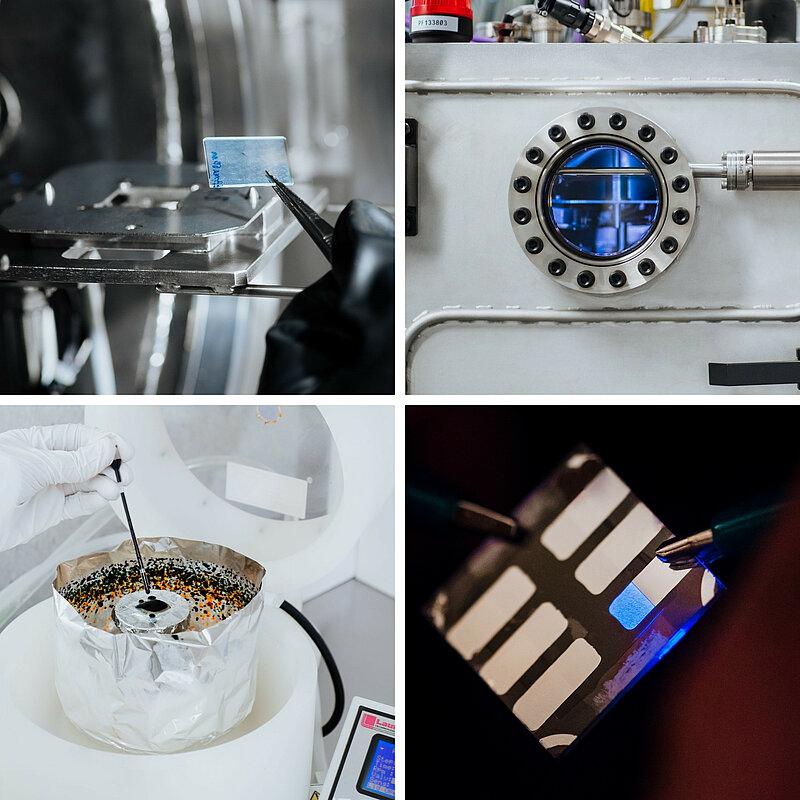

Thin films | Microfluidics | OLEDs | Polymer photonics | 1D and 2D material nanodevices |

|  |  |  |  |

| Wide range of thin film deposition techniques and development of new materials | Using PDMS and alternative non-absorbing materials we are focusing on applications in biology: organs on chips and extracellular vesicles | Full fabrication and characterization cycle | Interferometers, modulators, ring resonators and other devices utilizing non-linear properties of organic materials | Graphene and nanowires based sensors and other devices |

Technologies

-

THIN FILM DEPOSITIONS

Thermal evaporation, magnetron sputtering (DC,RF, reactive, HIPIMS), pulsed laser deposition, atomic layer deposition, plasma enhanced chemical vapor deposition, ink-jet printing, spin-coating -

LITHOGRAPHY

Electron beam lithography, UV lithography, direct laser writer -

ETCHING

Reactive ion etching, wet etching -

CHARACTERIZATION

SEM-FIB, EDS, EBDS, STEM, TEM, profilers, probe station, optical microscopes, drop shape analyzer, XPS, EPR and other spectroscopical characterization available -

OTHER

Glove boxes, wire bonders, HMDS oven, plasma asher, 3D printing, fume hoods etc. Electrochemical investigation and gas analysis

Opportunities

With its extensive facilities, the Nanotechnology centre offers a wide spectrum of opportunities for R & D activities.

It is an open-access research laboratory and hosts both elite academic research and a multitude of industrial collaborations.

Cleanroom Operational group:

Cleanroom operational group is responsible for the safety and infrastructure of the ISSP UL cleanroom, such as ventilation and exhaust systems, electricity, clean dry air, house gases etc.

ON-CALL DUTY (24/7)

M: +371 20221109

Cleanroom Operational group members:

Head of ISSP UL Cleanroom: Valdis Korsaks

M: +371 6437272

E: Valdis.Korsaks@cfi.lu.lv

Service Engineer: Janis Lipenits

M: +371 29479648

E: Lipenits.Janis@cfi.lu.lv

IT Service: Jānis Busenbergs

M: +371 26374996

E: Janis.Busenbergs@cfi.lu.lv

ISSP UL Director: Andris Anspoks

P: +371 67187816

E: Andris.Anspoks@cfi.lu.lv

1. ISSP UL employee

- Contact to Head of ISSP UL Cleanroom

- General Safety Training

- Cleanroom safety and correct behaviour training (4.5 h) + LIMS training (1 h), (LIMS if needed)

- Get access to the cleanroom

2. External academic, external industrials, and other users

- Contact to MATERIZE Projects Unit info@materize.com.

- to MATERIZE Projects Unit confirm external user’s industrial relations with ISSP UL

- General Safety Training

- Cleanroom safety and correct behaviour training + LIMS training (if needed)

- Get access to the cleanroom

MATERIZE Projects Unit contacts:

T: +371 29234818

E: info@materize.com

Responsible for General safety training:

Raitis Siatkovskis

M: +371 29459864

E: Raitis.Siatkovskis@cfi.lu.lv

Responsible for Cleanroom safety and correct behaviour training:

Dr. Phys. Valdis Korsaks

M: +371 26437272

E: Valdis.Korsaks@cfi.lu.lv

The user must apply before course. Write an email to responsible for cleanroom safety and correct behaviour training (write date when you plan attend the course).